API CORROSION/EROSION FOUR SECTION PLATE

API CORROSION/EROSION FOUR SECTION PLATE Corrosion, Erosion, and Lamination UT Thickness Training & Certification Plates Specification: • Plates will be divided into 4 quadrants with machined scribe lines with each quadrant identified Alpha/Numerically on plate. • The opposing side (host side) of the plate will host 2 randomly placed simulated corrosion, erosion and/or laminations. • The quadrant selection and indication depth will be selected randomly or selected by the client.

API CORROSION/EROSION Pipe

API CORROSION/EROSION Pipe • 4” OD with variable schedules at Sch10 (0.156”), Sch80 (0.337”) and Sch160 (0.531”) • The pipe is a cut 180° segment with 12” axial length. • The ID has 3 machined steps; 0.156”, 0.337” and 0.531”, each step is 4” in axial length. Specifications: • Each wall thickness/step will contain 1 or 2 ID surface indications. • The indications include: • Corrosion • Random Pitting • Erosion • The indication depths will vary depending on the pipe wall thickness. • Typical depths range from 25%, 50% and 75% through wall. • The overall size of the surface indication will vary as to the depth of the indication. • The indication depth will be stated at the deepest point of each indication. Pitting indications will be based on the deepest pit.

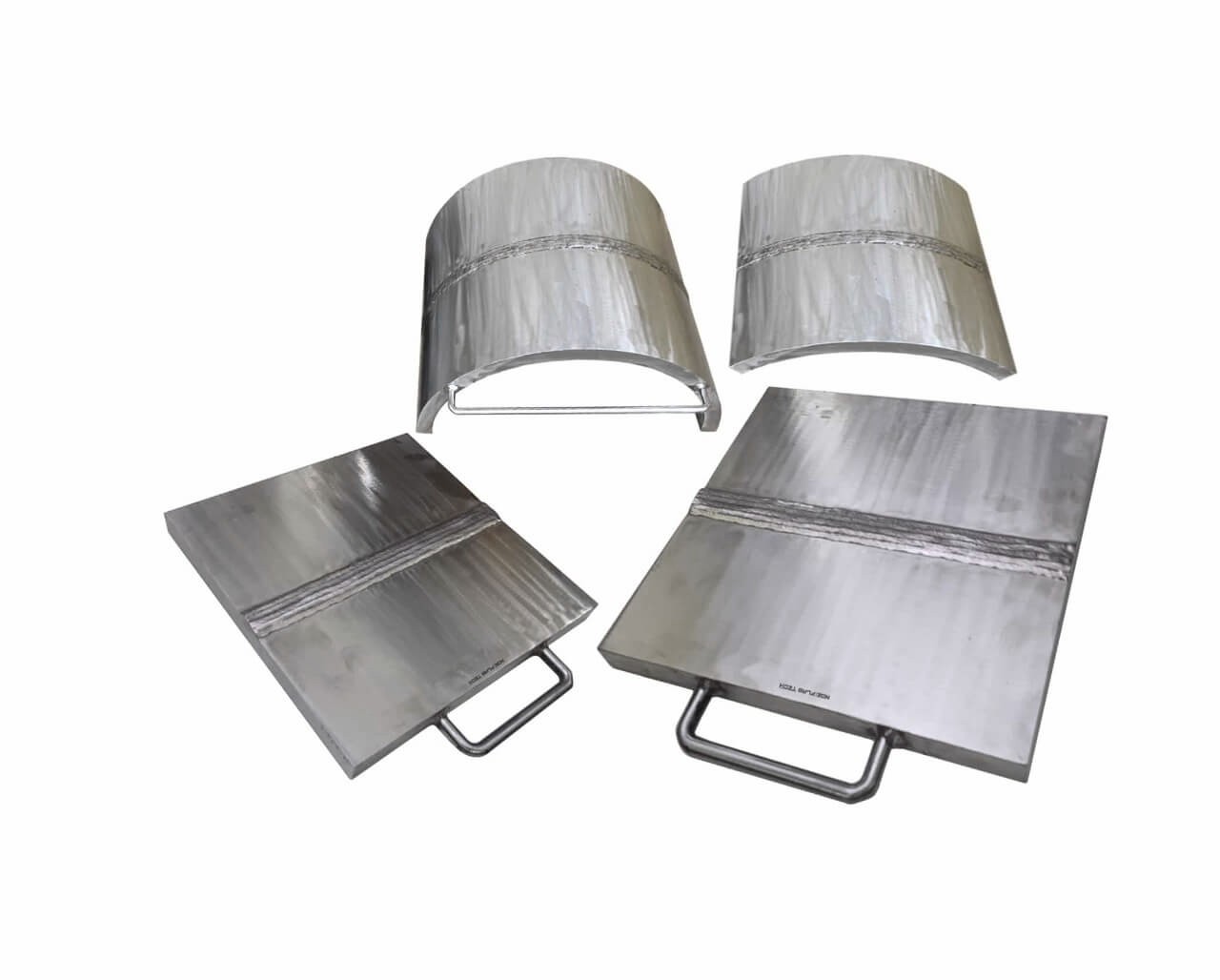

API UT 1 Qualification Test Specimen Kit

API UT 1 Qualification Test Specimen Kit Geometry: Kit contains 4 Specimens: (1) Double V Plate @ 15.0"(L) x 12.0" (W) x 1.0" (T). (1) Single V Plate @ 12.0" (L) x 10.0" (W) x 0.5" (T). (1) Pipe @ 8" Sch80 (360°) wall thick 0.5" x 12.0" (L). (1) Pipe @12" Sch80 (180°) wall thick 0.72" x 12.0" (L). Flaws: 3 per specimen, 12 total Documentation: NDT Verification Reports, and Test Sheets. Designed in accordance with Fig.1of API-UT-1 Generic Procedure for the Ultrasonic Examination of Ferritic Welds, this kit contains a total of 4 specimens. NOTE: Customized Evaluation Test Block and Flaw Specimen also available. For any special artificial flaws as per client requirement, please request with detail by mail.

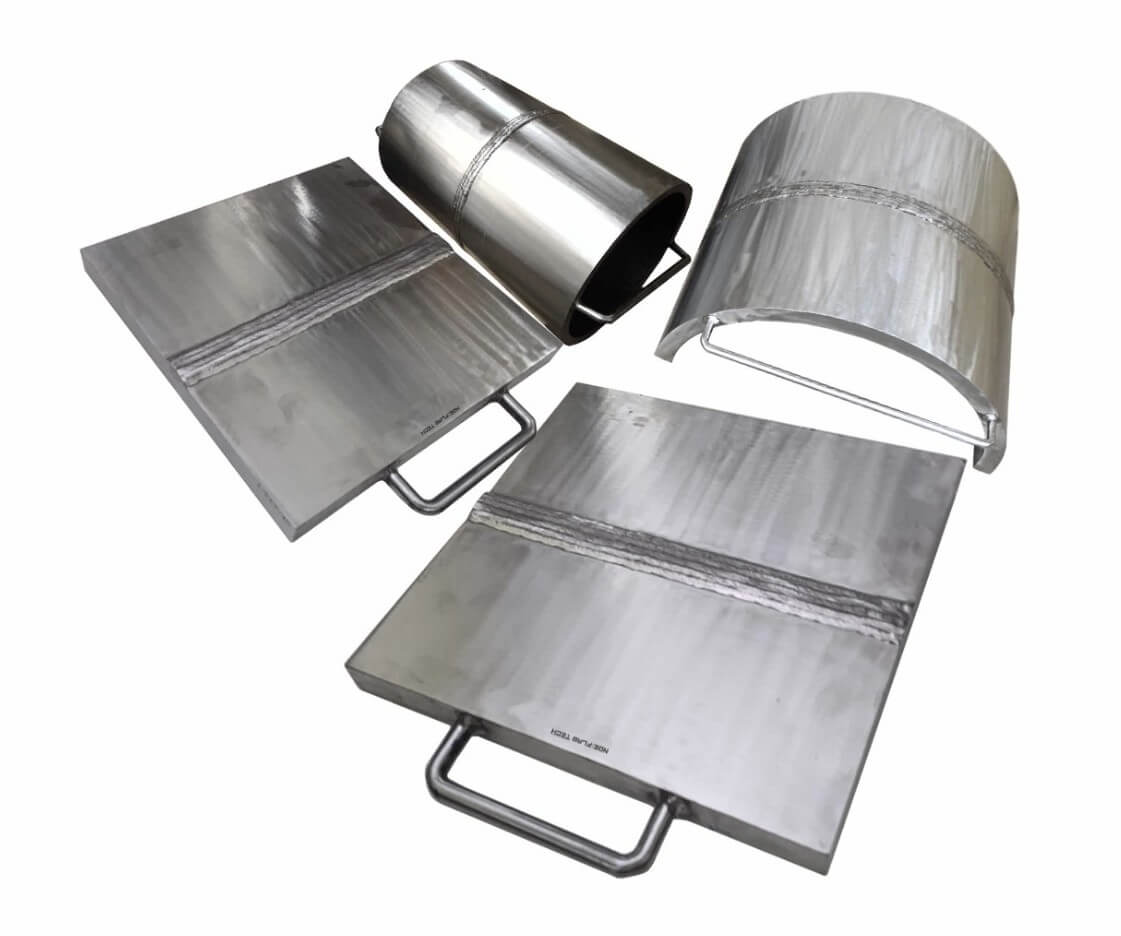

API UT 1 Qualification Specimen Mini Kit

API UT 1 Qualification Specimen Mini Kit Geometry: Kit contains 4 Specimens: (1) Double V Plate @ 1” (T) x 7.5” (W) x 6” (L) (1) Single V Plate @ 0.5” (T) x 6” (W) x 5” (L) (1) Pipe @ 8” Sch80 (180°) wall thick 0.5" x 6” (L) x Arc length 12.5" (1) Pipe @12” Sch80 (90°) wall thick 0.72" x 6” (L) x Arc length 10.0" Flaws: 2 per specimen, 8 total Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Designed in accordance with Fig.1of API-UT-1 Generic Procedure for the Ultrasonic Examination of Ferritic Welds, this kit contains a total of 4 specimens. NOTE: Customized Evaluation Test Block and Flaw Specimen also available. For any special artificial flaws as per client requirement, please request with detail by mail.

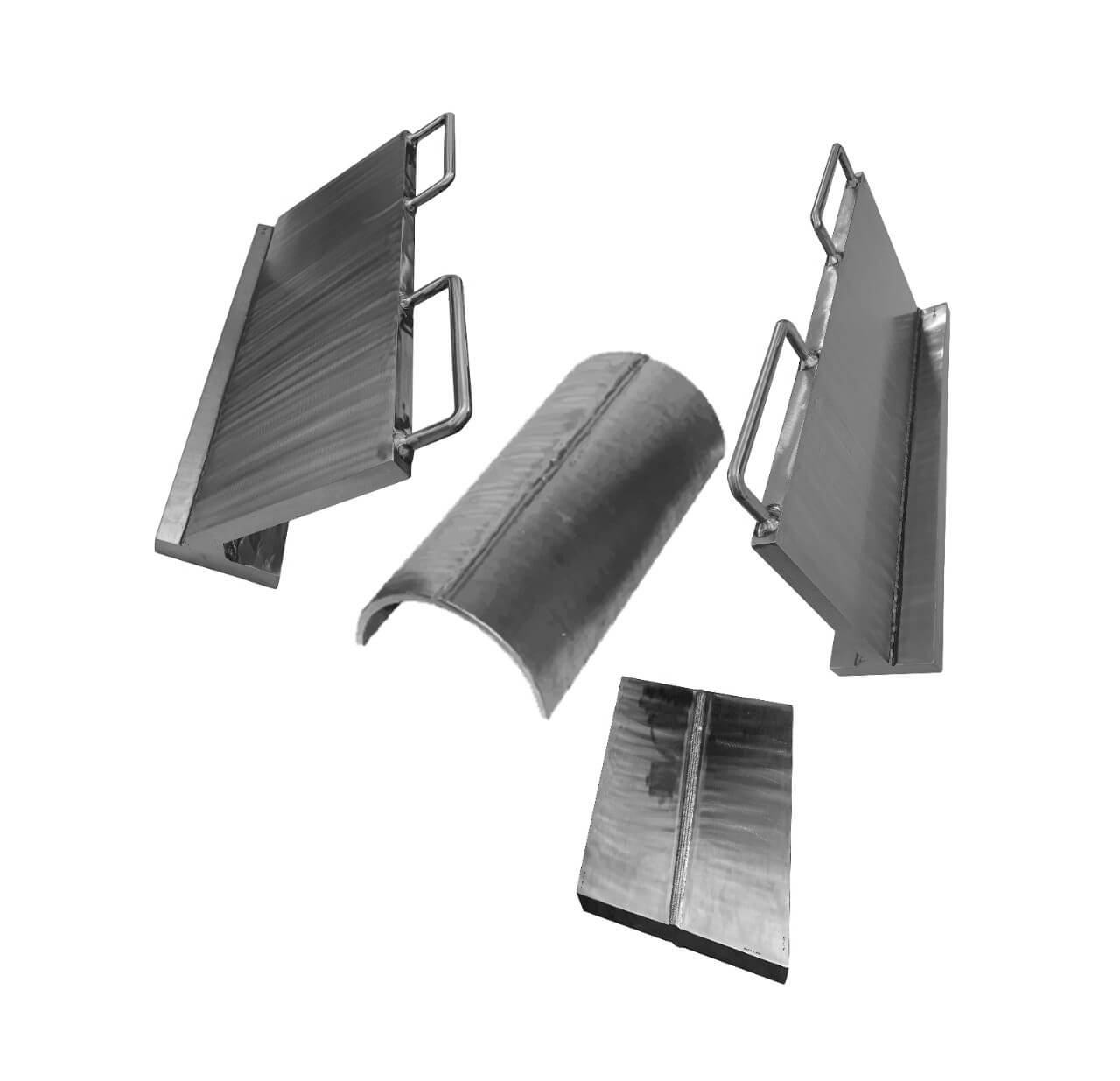

API RP-2X Practice Test Kit

API RP-2X Practice Test Kit Designed in the spirit of API RP-2X, these specimens offer a technician advanced training in UT flaw detection & sizing in unique configurations. This kit is a great tool for conducting practical examinations, as well as preparing technicians for typical industry exams.

API RP-2X KIT

API RP-2X KIT API RP-2X Practice Specimens Kit: Set of 3 Specimens: • (1) 90° “T” Connection- 0.75″ (T) x 12″ (Weld Length) x 4″ (Base) x 8″ (Branch) • (1) 45° “Y” Connection- 0.75″ (T) x 12″ (Weld Length) x 4″ (Base) x 8″ (Branch) • (1) 60° “Y” Connection.- 0.75″ (T) x 12″ (Weld Length) x 4″ (Base) x 8″ (Branch)

Crack Sizing Bars

Crack Sizing Bars • Quantity: Set of 10 • Bar Specifications: • Carbon Steel • 10mm (T) with Single V Groove • Bars will be 75mm (W) x 250mm (L) • The crowns may be as welded or ground flush–client choice • Weld root will be as welded • Weld will be located in the center of 250mm bar • Each bar will contain a single surface connected “thumbnail”, “straight” or “asymmetrical” shaped crack — client choice • The crack ID surface length will span the 75mm width of the bar • The crack through wall depths • 80%, 70%, 60%, 50%, 45%, 40%, 30%, 20%, 10%, 10% and 5% • Depths can be adjusted as needed • The asymmetrical-shaped cracks may have 2 specified depths • The crack locations will vary from HAZ, Centerline, Toe and Root as requested by client • Bar sides will be dressed with sharp edges chamfered. • Flaw Tolerance +/- 0.080 • Manufacturing Drawings: • NDE Flaw Tech will provide the client a set of CAD drawings for their review and approval prior to the start of production. • Final Documentation: • Includes C of C, “As Built” CAD drawings, Measuring & Test Equipment Certificates and Test Sheets

Oil & Gas Sector UT

Oil & Gas Sector UT Qty: 1 This “NEW” UT Training and Testing of Flawed Specimen Kit is the premier preparation tool for the API QUTE – Detection, QUSE – Sizing and the ASNT ISQ Oil & Gas Sector Shear Wave exams. This kit was designed and manufactured to emulate the API & ASNT OGUTSW4 Rev 00 Protocols. The Kit assists in the training and testing of UT Technicians for both Conventional and PAUT. There are 12 Flaws which cover both fabrication and in-service indications to be evaluated in four specimens. It also comes with our complete document package included in the purchase price. Material: • Carbon Steel, A36 plate and A106B pipe SMLS

API CORROSION/EROSION Sixteen Section Plate

API CORROSION/EROSION Sixteen Section Plate Corrosion, Erosion, and Lamination UT Thickness Training & Certification Plates Specification: • Plates will be divided into 16 sections with machined scribe lines with each quadrant identified Alpha/Numerically on plate. • The opposing side (host side) of the plate will host 4 randomly placed simulated corrosion, erosion and/or laminations. • The quadrant selection and indication depth will be selected randomly or selected by the client. • The through wall depths of the indications will vary but the target depths will range from ¼, ½ & ¾ T. • The recorded depth of the corrosion indications will be based on the deepest spot within the field of corrosion. • The side of the carbon plate hosting the indications will be painted with a “Rust-Oleum” type paint to assist in preventing additional corrosion. • The host side of the plate will be covered with a “removable” cover plate Documentation: • Certificate of Conformance, “As Built” CAD and Measuring & Test Equipment Certificates