EN 12223.jpeg)

Calibration Block No.1 (Metric Version) Special Alloy

Calibration Block No.1 (Metric Version) Special Alloy Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: Special Alloy

.jpeg)

Calibration Block No.1 (Metric Version) 1018 Steel

Calibration Block No.1 (Metric Version) 1018 Steel Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: 1018 Steel

EN 12223.jpeg)

Calibration Block No.1 (Metric Version) STAINLESS STEEL 304

Calibration Block No.1 (Metric Version) STAINLESS STEEL 304 Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: STAINLESS STEEL 304.

Calibration Block No.1 (Metric Version) STAINLESS STEEL 316

Calibration Block No.1 (Metric Version) STAINLESS STEEL 316 Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: STAINLESS STEEL 316.

.jpeg)

Calibration Block No.1 (Metric Version) TITANIUM

Calibration Block No.1 (Metric Version) TITANIUM Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: TITANIUM.

EN 12223.jpeg)

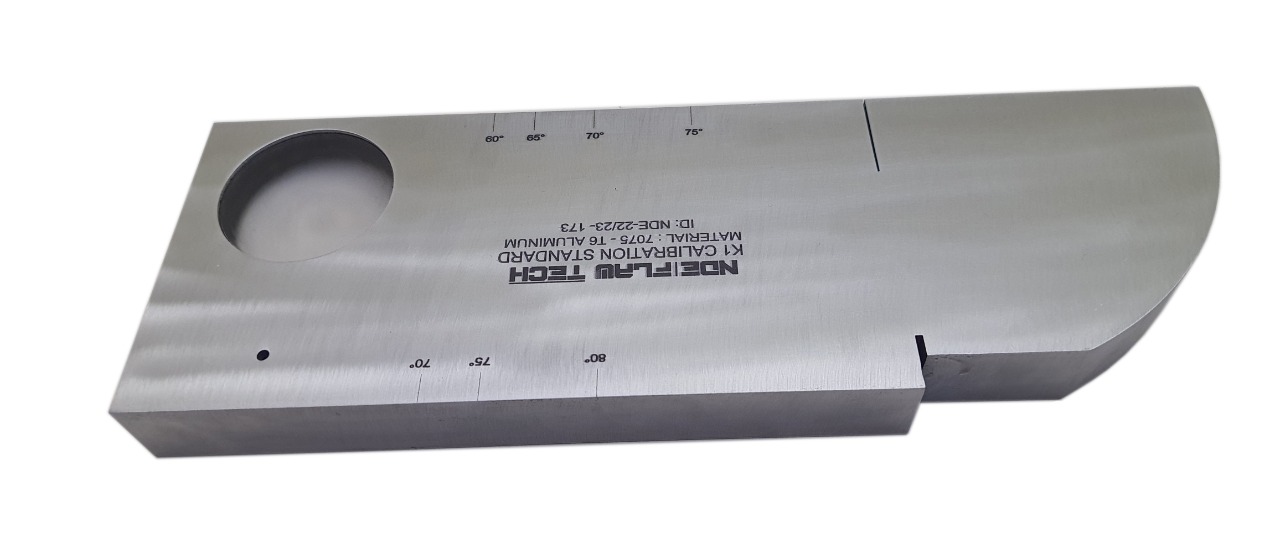

Calibration Block No.1 (Metric Version) ALUMINUM 7075-T6

Calibration Block No.1 (Metric Version) ALUMINUM 7075-T6 Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: ALUMINUM 7075-T6

.jpeg)

Calibration Block No.1 (Metric Version) INCONEL 625

Calibration Block No.1 (Metric Version) INCONEL 625 Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: INCONEL 625.

EN 12223.jpeg)

Calibration Block No.1 (Metric Version) MONAL 800

Calibration Block No.1 (Metric Version) MONAL 800 Calibration Block No.1 are used to calibrate instruments for both angle beam and normal incident inspections. Some of their uses include setting metal-distance and sensitivity settings, determining the sound exit point and refracted angle of angle beam transducers, and evaluating depth resolution of normal beam inspection setups. For calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. Our version of this block includes a 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with EN 12223 and ISO 2400. This block is not to be confused with the older style "V1/5 (A2)" Block from BS 2704, which is similar but contains a 1.5mm through-hole rather than a 3.0mm hole. See our test block store for more information on this block. Geometry: 100mm radius, 3.0mm and 50.0mm holes, engraved reference mark scales, and two optional slots at the zero point which provide calibrating signals at intervals of 100mm range. Dimensions: 300mm x 100mm x 25mm. Material: MONAL 800.