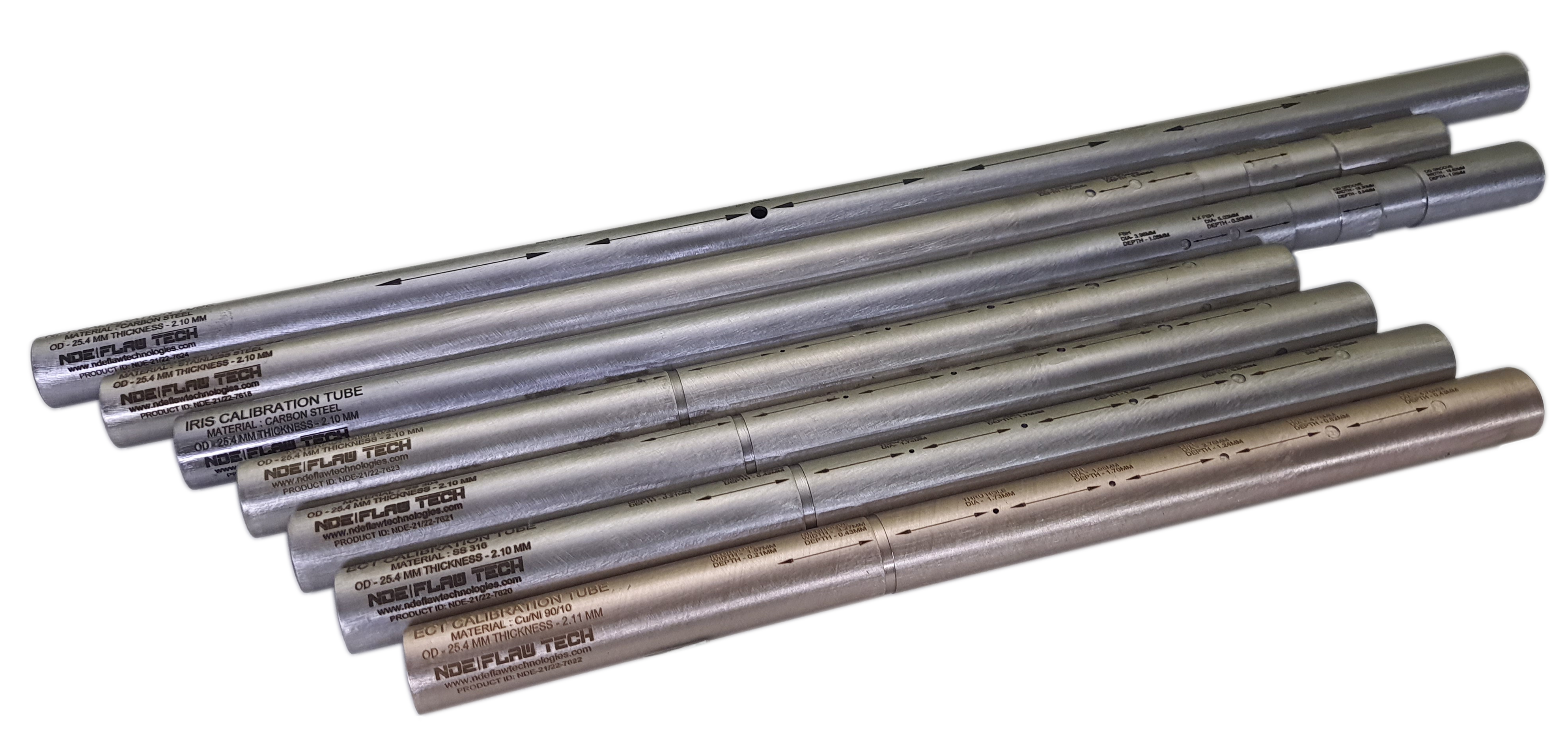

Eddy Current Testing Calibration Tube (ECT)

Price: $0.00

Part Number : NDE FLAW TECH-ECT CALIBRATION TUBE-40

Availability : In Stock

Description

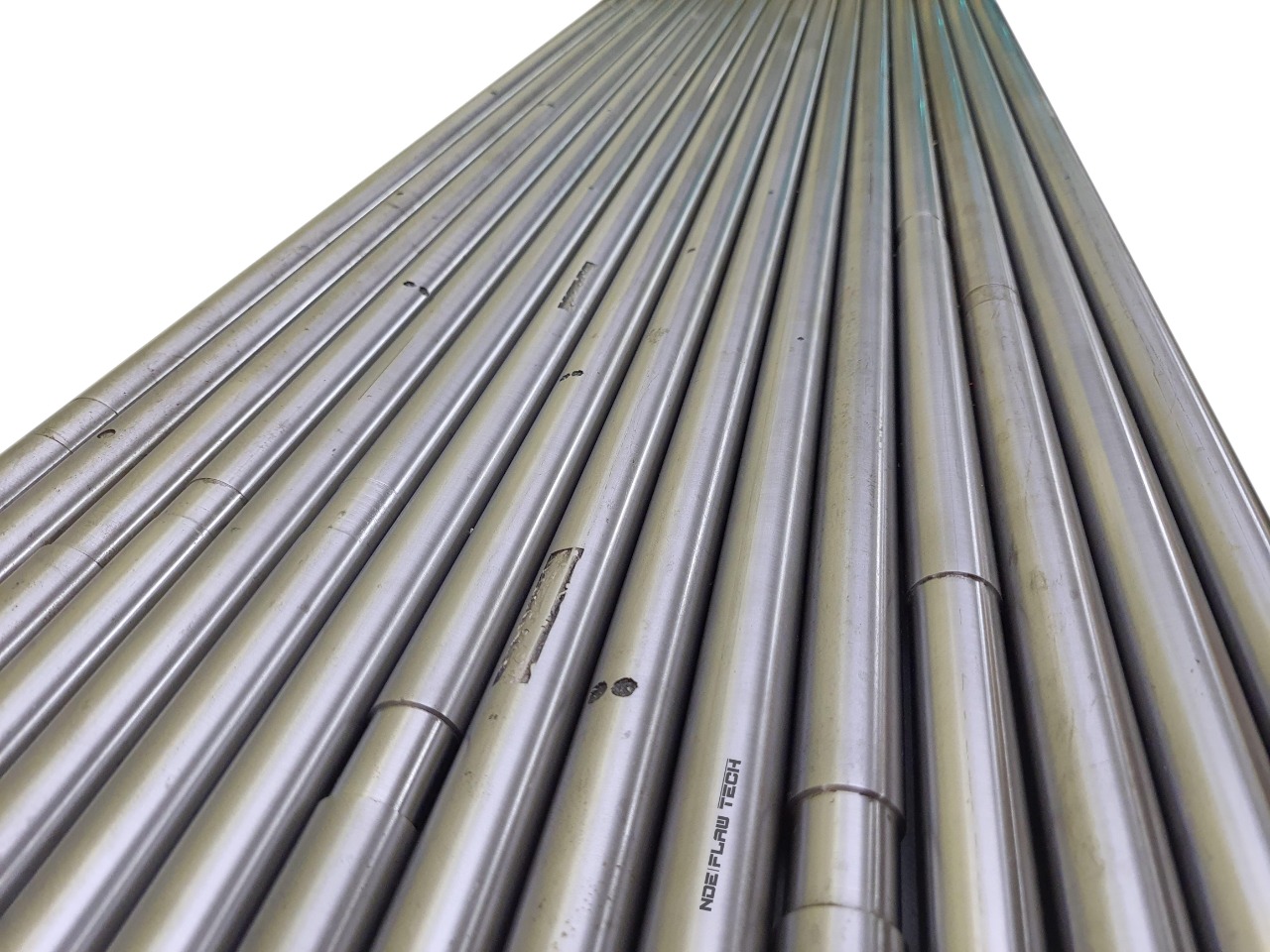

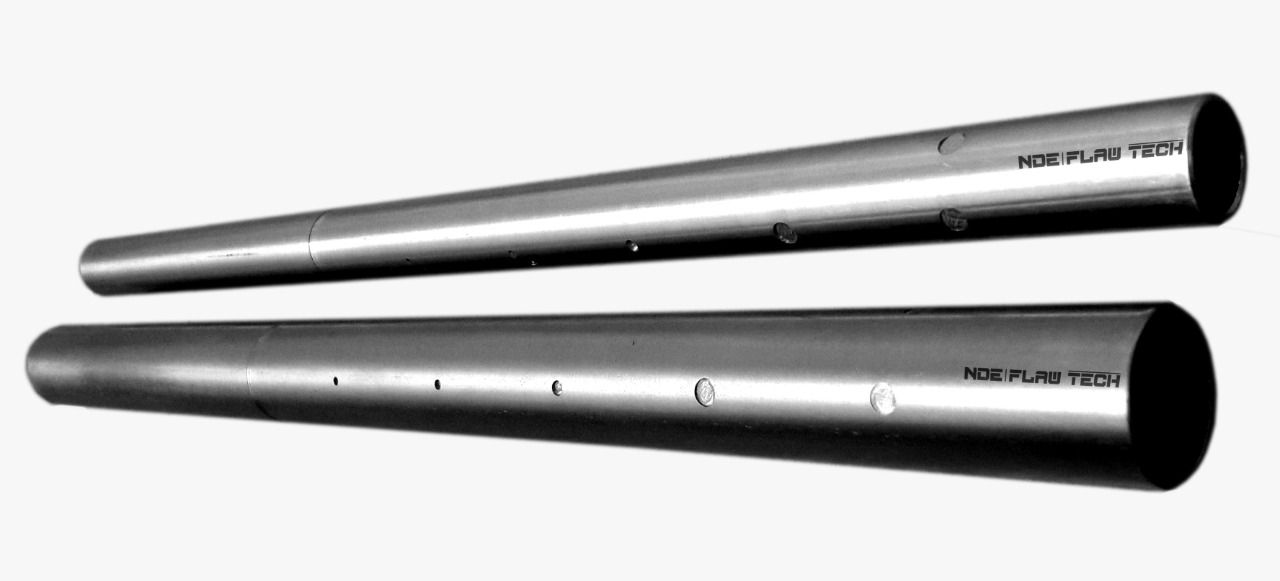

Eddy Current Tube Standards. Ready

to request a quote for a standard? Here's what we need... What is the material?

(Alloy, OD and Wall) Is NDE supplying the material or will it be

customer supplied? What defects are needed and what size? (most depths are

given in % of tube wall) Is there a specification the standard needs to comply

with? (ASME, etc.) If you have a drawing, or even a simple hand

sketch, please send that along as well. We specialize in custom eddy

current tubes, and have years of experience in machining a huge range

of defects. From TWHs and FBHs, OD and ID grooves, milled flats, and OD and ID

thinning bands, to ID FBHs, ID contoured flats, 120°/180° wearscars,

tapered flaws, and tube-to-tube wear,

|

Application |

Description |

ECT |

Comments |

|

Condensers |

Nonferromagnetic material Generally,

thin tubes made of brass, aluminum brass, cupronickel, or titanium. |

X |

– ECT is the recommended choice for

its speed and its accuracy. |

|

Air Conditioners |

Copper with low profile OD

fins Typical problem is circumferential cracking and wear in the land

area. |

X |

– ECT inspection with special

probes to detect circumferential cracks. These probes are normally

called AC probes. |

|

Heat Exchangers |

Nonferromagnetic

material Stainless steel, Cu/Ali |

X |

– ECT is the recommended choice for

its speed and accuracy.- IRIS can sometimes be used to confirm the sizing of

ID defects. |

|

Mildly ferromagnetic

material Duplex steel, SS439, Secure, Monel |

X |

– ECT is used only for thin tubes

(<1.6 mm) with saturation probes.- For thicker walls, it is better to use

RFT or MFL.- IRIS can sometimes be used to confirm the sizing of defects. |

.png)

.jpg)

.png)