ASTM E2491 Phased Array Assessment Block

ASTM E2491 Phased Array Assessment Block ASTM E2491 Phased Array Assessment Block is a general purpose Phased Array calibration block used for beam characterization and evaluation of system performance characteristics. Use it as a baseline block to determine long-term instrument performance changes, generate DAC curves and evaluate linear/angular resolution, focusing ability and beam steering capabilities. With a variety of targets, this small, lightweight block is also perfect for customer demonstrations of phased array ultrasonic capabilities. This block is also referred to as a “Type B” block.

Phased Array IIW ISO 19675 Calibration Block

Phased Array IIW ISO 19675 Calibration Block At the first glance, the PAUT IIW block looks very similar to the former IIW conventional UT block, but it allows carrying out far more checking and calibration functions. Usages such as wedge delay, grating lobes assessment, active element assessment, sensitivity equalization, plotting check, element assignment, etc. Beam angle (angle beam probe), First the delay law for the angle beam being assessed shall be configured. Then the probe index shall be determined, by positioning the probe to maximize the echo response from the 100mm radius. Using a fine-tip marker, a line is drawn on the wedge where the center point of the 100mm radius meets the wedge. Then the probe is moved to maximize the response from either the uppermost or lowermost 3mm diameter side drilled hole. Read the value of the angle indicated on the scribed markings to the nearest 0.5° to determine the actual refracted angle can now be read. Element assignment - A B-scan of the delay law acquisitions is displayed and the amplitude and time of the back wall signal for each element in the array is observed. If the element #1 is nearest the end of the PAUT calibration block it will have the shortest arrival time in pulse-echo and all subsequent elements should display a monotonic increase in arrival time. B-scan from a 64 element probe with the response seen from the V surface of the block. The response from each element is slightly greater in time than its next adjacent element indicating correct assignment of elements. The PAUT IIW Block, made in accordance with ISO 19675 was designed by an international committee of NDT experts with the express purpose of creating a globally accepted, standardized block for Phased Array Ultrasonic calibrations. Before the development of this spec, there were no international standards describing a specific block for calibrating PAUT systems.

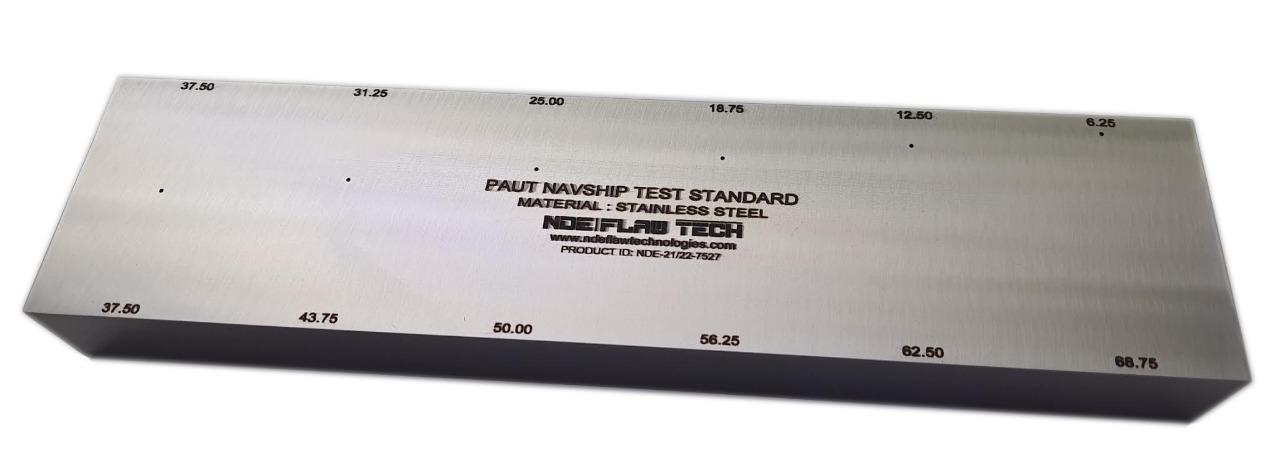

Phased Array Navships Test Block

Phased Array Navships Test Block This special Phased Array version of the popular NAVSHIPS block solves the problem of too many holes interfering with one another. Geometry: The block contains four holes at 1.2mm diameter drilled through the 30mm width.

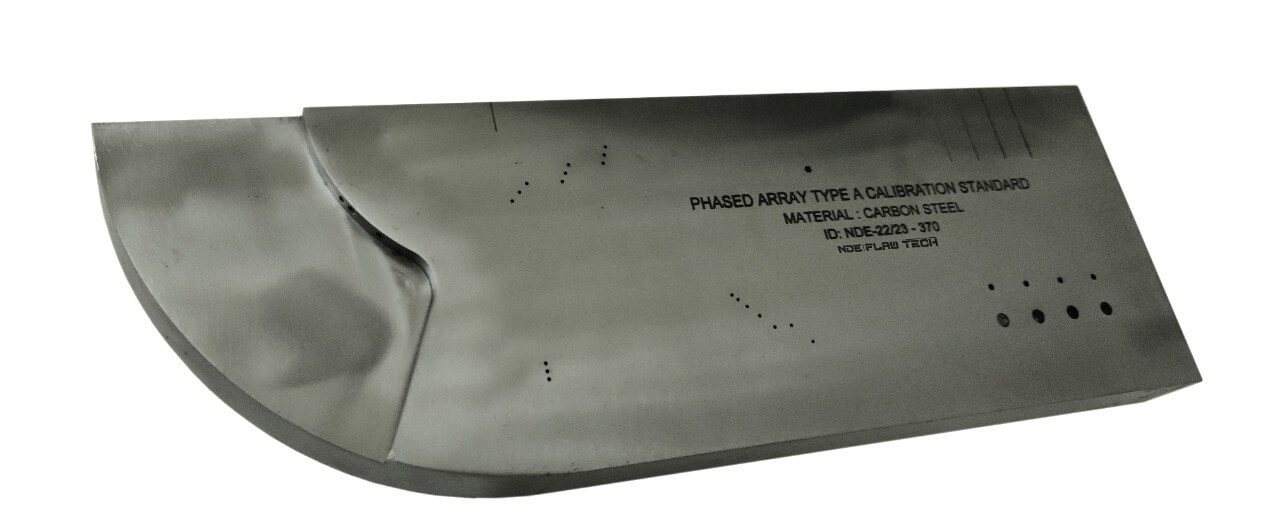

Phased Array "Type A" Block IIW-Type

Phased Array "Type A" Block IIW-Type Phased Array "Type A" Calibration Block is used during the initial setup and calibration of a phased array ultrasonic unit. This block can be used to perform tasks such as beam angle verification, calibration for wedge delay, sensitivity calibration, performing DAC/TCG and more. This block has similar dimensions to an IIW-Type Block, but has specially-engineered for phased array applications.

PAUT-Phased Array Standard Calibration Blocks

PAUT-Phased Array Standard Calibration Blocks Phased Array Calibration Standard Blocks are used for angle beam verification, probe angle exit points, calibration for wedge delay, sensitivity and DAC/TCG for thicknesses up to 50mm. The reference block shall be used which allows a minimum of a 3 point TCG establishment throughout the range specified in the scan plan for all configured angles . The block shall be made of sufficient thickness and length to allow calibration of reflectors throughout the entire examination volume to be tested. Each reference block shall have at least three side drilled holes at a range of depths to cover the entire material range to be tested. Each hole shall be detected by the PAUT system as configured per the scan plan and sensitivities shall be adjusted as necessary to provide sensitivity equal to or greater than SSL.

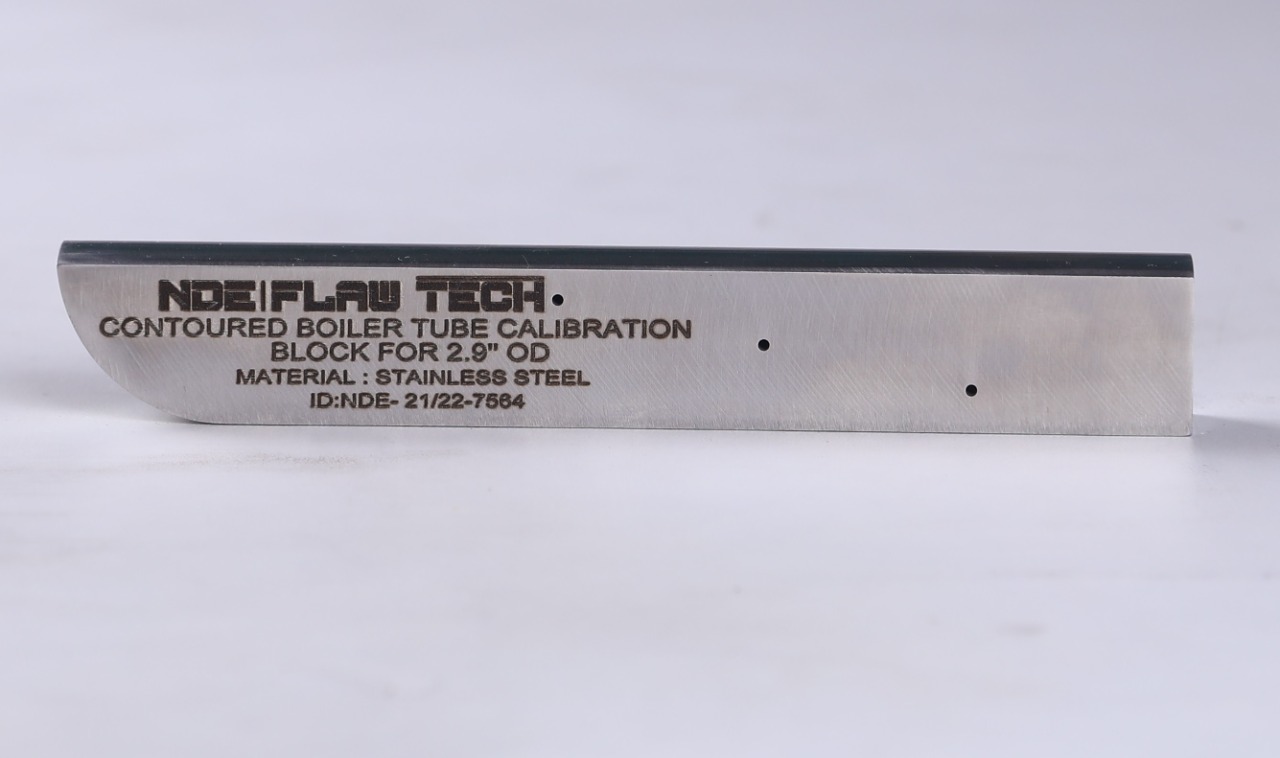

PAUT-Contoured Boiler Tube Calibration Block

PAUT-Contoured Boiler Tube Calibration Block Contoured Boiler Tube Calibration Block (BTB) – boiler tube block for calibrating low profile PA probes for use with Bracelet scanner, 3 x 1.5mm dia SDH and contoured for 1.9" OD (1.5" NPS) (other contours available incl. 2" / 2.5" / 3" / 3.5" / 4" NPS). 25 x 20 x 165mm please contact us through an email and to know more details about Boiler Tube Calibration Block Our knowledgeable customer service staff is happy to assist you.

PAUT- Standard Notch Calibration Block

PAUT- Standard Notch Calibration Block The PAUT- Standard Notch Calibration Block has been specially designed for use with Phased Array instruments used for sizing of OD and ID-connected cracks.

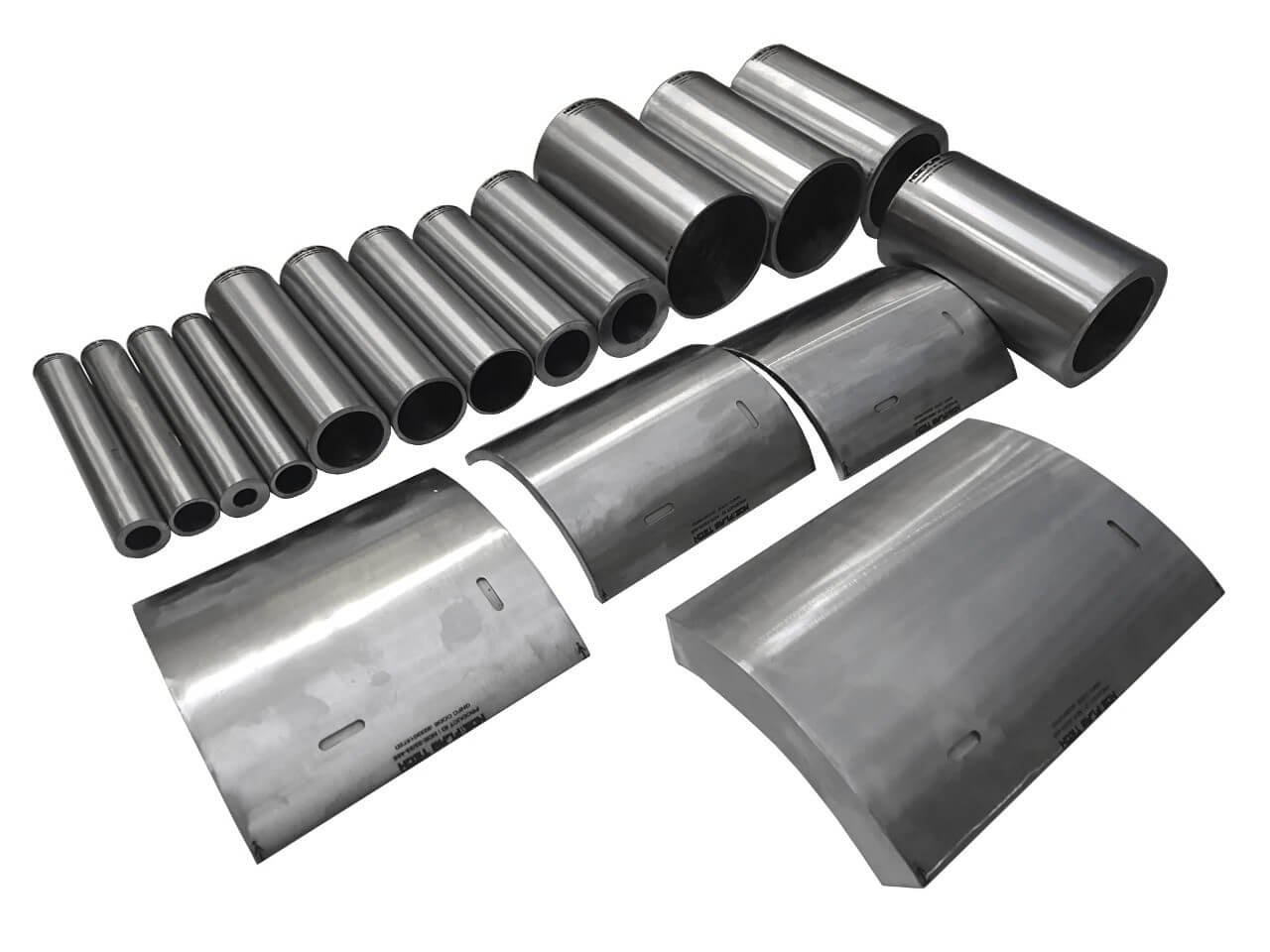

ASME Type Phased Array Pipe Calibration Block

ASME Type Phased Array Pipe Calibration Block Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well.